Product Description

Feuling Reaper Camshaft for Harley Davidson Twin Cam

High performance camshafts by Feuling for Twin Cam engines. Available in different configurations to suit your performance needs.

Features:

- Produces more power and torque in the riding rpm range, improving throttle response, acceleration and fuel mileage

- Smooth camshaft lobe ramps are easier on valvetrain components and eliminate excessive valvetrain noise and wear

- Wide lobe separations produce wide power bands

- Optimized cam timing provides easy starting without the need for mechanical devices or compression releases

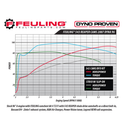

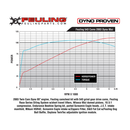

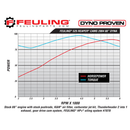

- Dyno proven and track tested

- Feuling camshaft installation kits recommended

- Camshaft Set is 2 camshafts

- See cam specific features below

525 Camshaft

- Great bolt-in camshaft upgrade for stock 88” and 96” engines also performs very well in 103” strokers and will respond well to increased compression and cylinder head work

- Designed to increase torque band width and increase fuel economy

- Produces strong low- and mid-range power with linear horsepower and torque curve

- Can be used with factory valve springs, pushrods and lifters

- Increases throttle response and eases starting

- Strongest from 1750-5500 rpm

543 Camshaft

- Excellent bolt-in camshaft for stock to mild 96” and 103” engines and works well in 88” and 95” engines

- The ‘Freeway Flyer’, great camshafts for those who want more top end power than the 525 cams without sacrificing low end torque

- Extremely smooth cam lobe layout maintains quiet valve train and produces the smoothest cruise power band available

- Cam is easy starting, increases throttle response and fuel mileage. Responds well to increased compression ratio, performance exhaust and a high-flow air cleaner

- Performance high lift valve springs are required on 99-04 engines and performance pushrods and lifters are recommended but not required

- Strongest from 1900-6000 rpm

574 Camshaft

- Wicked power band for modified engines and an excellent bolt-in for stock 96”, 103” and 110” engines, a great all-around camshaft with solid low end performance and mind-blowing mid and top end power

- Responds well to modified cylinder heads, increased compression ratio, performance exhaust and intake systems

- Extremely smooth cam lobe design creates a smooth and quiet valve train

- Performance valve springs required on 99-04 engines and performance pushrods and lifters recommended

- Strongest from 2100-6000 rpm

594 Camshaft

- Fierce performing camshaft for an array of engine sizes, for large displacement 103”, 110” and 124” engines looking for a superior torque band with excellent horsepower gains in heavy bikes (2200-6250 rpm). As well as for smaller high-revving displacement 95” style engines in lighter bikes looking to twist the throttle and tap into some horsepower (2500-6800 rpm)

- Large displacements respond well to increased compression ratio and smaller displacements will require it

- 594 cams require high-performance valve springs, pushrods, lifters, carburetor and or throttle body work, performance exhaust, intake and clutch.

630 Camshaft

- Vicious power gains, wide streetable power band from high-lift-profile camshaft for high-performance engines with highly modified cylinder heads and compression ratio

- Carburetor and/or throttle body work required along with a performance exhaust and intake system

- Maintains low end performance with eye-blurring mid and top end power

- High-performance valve springs, pushrods and lifters required

- Strongest from 2500-9000 rpm

General product notes:

Note: Gear drive camshafts come without inner & outer drive gears. Gears must be purchased separately. Installation is a simple press-on installation. If you have gears from your current Andrews or S&S gear drive cam, these can be re-used or a new S&S set purchased. S&S Cam Gear Kit available here.

Note: 594 & 630 high lift cams require adjustable pushrods. 525, 543 and 574 cams are compatible with stock pushrods.

Note: When converting from hydraulic chain tensioners on 06-17 Dyna, 07-17 Softail and 07-16 Touring to gear drive cams, block-off plates are required for the oil holes. Block off kit available here.

Note: Chain drive cams for 99-06 Twin Cam are for use with stock 00-06 Twin Cam splined outer drive gears, for installation on 99 Twin Cam motors you must purchase a splined outer drive sprocket separately, S&S recommends using Andrews Splined Outer Cam Driven Gear 34T.

Cam Chest installation instructions for Twin Cam engines available here

Cam specifications

| GRIND | VALVE LIFT | OPEN | CLOSE | DURATION @ 0,053” | LIFT @ TDC | LOBE CENTERLINE |

| 525 | ||||||

| Intake | 525 | 4° | 42° | 226° | 0,099” | 109° |

| Exhaust | 535 | 51° | 5° | 236° | 0,112” | 113° |

| 543 | ||||||

| Intake | 543 | 15° | 43° | 238° | 0,160” | 104° |

| Exhaust | 553 | 56° | 12° | 248° | 0,140” | 112° |

| 574 | ||||||

| Intake | 574 | 15° | 45° | 240° | 0,163” | 105° |

| Exhaust | 574 | 61° | 14° | 255° | 0,143” | 113,5° |

| 594 | ||||||

| Intake | 594 | 19° | 56° | 255° | 0,190” | 108,5° |

| Exhaust | 604 | 64° | 16° | 260° | 0,167” | 114° |

| 630 | ||||||

| Intake | 630 | 20° | 58° | 258° | 0,188” | 109° |

| Exhaust | 630 | 60° | 19° | 263° | 0,171” | 112,5° |

Timing and duration measured at zero lash and .053" tappet lift off base circle. To avoid coil bind, allow min. .030" more free valve travel than the max. valve lift that is mentioned. To achieve adequate valve spring clearance, several higher lift top collars are available which require no machining.

Variant: 00-06 Softail - 525 Chain Drive Cams

SKU: A020-468425

MPN: 1001

DPN: 566020

Variant: 00-06 Softail - 525 Gear Drive Cams

SKU: A000-468405

MPN: 1004

DPN: 566000

Variant: 00-06 Softail - 543 Chain Drive Cams

SKU: A021-468426

MPN: 1000

DPN: 566021

Variant: 00-06 Softail - 543 Gear Drive Cams

SKU: A001-468406

MPN: 1021

DPN: 566001

Variant: 00-06 Softail - 574 Chain Drive Cams

SKU: A022-468427

MPN: 1002

DPN: 566022

Variant: 00-06 Softail - 574 Gear Drive Cams

SKU: A002-468407

MPN: 1007

DPN: 566002

Variant: 00-06 Softail - 594 Gear Drive Cams

SKU: A003-468408

MPN: 1302

DPN: 566003

Variant: 00-06 Softail - 630 Gear Drive Cams

SKU: A004-468409

MPN: 1010

DPN: 566004

Variant: 07-17 Softail - 525 Chain Drive Cams

SKU: A023-468428

MPN: 1006

DPN: 566023

Variant: 07-17 Softail - 525 Gear Drive Cams

SKU: A005-468410

MPN: 1005

DPN: 566005

Variant: 07-17 Softail - 543 Chain Drive Cams

SKU: A024-468429

MPN: 1020

DPN: 566024

Variant: 07-17 Softail - 543 Gear Drive Cams

SKU: A006-468411

MPN: 1022

DPN: 566006

Variant: 07-17 Softail - 574 Chain Drive Cams

SKU: A025-468430

MPN: 1009

DPN: 566025

Variant: 07-17 Softail - 574 Gear Drive Cams

SKU: A007-468412

MPN: 1008

DPN: 566007

Variant: 07-17 Softail - 594 Gear Drive Cams

SKU: A008-468413

MPN: 1304

DPN: 566008

Variant: 07-17 Softail - 630 Gear Drive Cams

SKU: A009-468414

MPN: 1011

DPN: 566009

Variant: 99-06 Touring - 525 Chain Drive Cams

SKU: A020-468425

MPN: 1001

DPN: 566020

Variant: 99-06 Touring - 525 Gear Drive Cams

SKU: A000-468405

MPN: 1004

DPN: 566000

Variant: 99-06 Touring - 543 Chain Drive Cams

SKU: A021-468426

MPN: 1000

DPN: 566021

Variant: 99-06 Touring - 543 Gear Drive Cams

SKU: A001-468406

MPN: 1021

DPN: 566001

Variant: 99-06 Touring - 574 Chain Drive Cams

SKU: A022-468427

MPN: 1002

DPN: 566022

Variant: 99-06 Touring - 574 Gear Drive Cams

SKU: A002-468407

MPN: 1007

DPN: 566002

Variant: 99-06 Touring - 594 Gear Drive Cams

SKU: A003-468408

MPN: 1302

DPN: 566003

Variant: 99-06 Touring - 630 Gear Drive Cams

SKU: A004-468409

MPN: 1010

DPN: 566004

Variant: 07-16 Touring - 525 Chain Drive Cams

SKU: A023-468428

MPN: 1006

DPN: 566023

Variant: 07-16 Touring - 525 Gear Drive Cams

SKU: A005-468410

MPN: 1005

DPN: 566005

Variant: 07-16 Touring - 543 Chain Drive Cams

SKU: A024-468429

MPN: 1020

DPN: 566024

Variant: 07-16 Touring - 543 Gear Drive Cams

SKU: A006-468411

MPN: 1022

DPN: 566006

Variant: 07-16 Touring - 574 Chain Drive Cams

SKU: A025-468430

MPN: 1009

DPN: 566025

Variant: 07-16 Touring - 574 Gear Drive Cams

SKU: A007-468412

MPN: 1008

DPN: 566007

Variant: 07-16 Touring - 594 Gear Drive Cams

SKU: A008-468413

MPN: 1304

DPN: 566008

Variant: 07-16 Touring - 630 Gear Drive Cams

SKU: A009-468414

MPN: 1011

DPN: 566009

Variant: 99-05 Dyna - 525 Chain Drive Cams

SKU: A020-468425

MPN: 1001

DPN: 566020

Variant: 99-05 Dyna - 525 Gear Drive Cams

SKU: A000-468405

MPN: 1004

DPN: 566000

Variant: 99-05 Dyna - 543 Chain Drive Cams

SKU: A021-468426

MPN: 1000

DPN: 566021

Variant: 99-05 Dyna - 543 Gear Drive Cams

SKU: A001-468406

MPN: 1021

DPN: 566001

Variant: 99-05 Dyna - 574 Chain Drive Cams

SKU: A022-468427

MPN: 1002

DPN: 566022

Variant: 99-05 Dyna - 574 Gear Drive Cams

SKU: A002-468407

MPN: 1007

DPN: 566002

Variant: 99-05 Dyna - 594 Gear Drive Cams

SKU: A003-468408

MPN: 1302

DPN: 566003

Variant: 99-05 Dyna - 630 Gear Drive Cams

SKU: A004-468409

MPN: 1010

DPN: 566004

Variant: 06-17 Dyna - 525 Chain Drive Cams

SKU: A023-468428

MPN: 1006

DPN: 566023

Variant: 06-17 Dyna - 525 Gear Drive Cams

SKU: A005-468410

MPN: 1005

DPN: 566005

Variant: 06-17 Dyna - 543 Chain Drive Cams

SKU: A024-468429

MPN: 1020

DPN: 566024

Variant: 06-17 Dyna - 543 Gear Drive Cams

SKU: A006-468411

MPN: 1022

DPN: 566006

Variant: 06-17 Dyna - 574 Chain Drive Cams

SKU: A025-468430

MPN: 1009

DPN: 566025

Variant: 06-17 Dyna - 574 Gear Drive Cams

SKU: A007-468412

MPN: 1008

DPN: 566007

Variant: 06-17 Dyna - 594 Gear Drive Cams

SKU: A008-468413

MPN: 1304

DPN: 566008

Variant: 06-17 Dyna - 630 Gear Drive Cams

SKU: A009-468414

MPN: 1011

DPN: 566009

Shipping and Delivery Times

All orders are shipped from our warehouse in Falkenberg, Sweden. We work hard to get them moving quickly!

Stock status explained:

- In stock: Ready to ship to you within the time listed. Packages usually arrive 2–4 business days after dispatch depending on your location.

- Sold Out: Currently out of stock at Customhoj, but we expect to have it back soon! Please feel free to contact us for information on when the product will be available again.

If a product has multiple variants (like sizes or colors), the stock status updates automatically as you select your option.

Our goal is simple, to get your order to you as fast as possible!

30-Day Hassle-Free Returns - No Questions Asked

If you are not entirely satisfied with your order, whether you need to change sizes or something else, we offer a full 30-day return policy from the day you receive your order. Return shipping costs apply.

Please note that the right to return does not apply to products that are personalized, or manufactured upon order. See our return policy for complete details and conditions.

You may also like

Biker favourites